Verification

In order to realize the engineering and commercialization of magnetorheological fluids, Keyi International has established a number of magnetorheological fluid raw material testing laboratories, formulation and process laboratories, product performance characterization testing laboratories and product reliability laboratories in Qingdao. The professional laboratory has successfully realized the commercialization of magnetorheological fluid, and the comprehensive performance of the product far exceeds that of foreign brands.

At present, Keyi International Intelligent Suspension has realized the mass production and sales of magnetorheological fluid products.

Evaluation Criteria for Commercial Grade Magnetorheological Fluids

In the process of commercialization of magnetorheological fluids, Keyi International Intelligent Suspension systematically analyzes and sorts out the evaluation standards of commercial magnetorheological fluids based on market-oriented and actual engineering needs, and summarizes 12 According to the performance requirements, Keyi International's product quality specifications have been formed.

Low zero field viscosity:

It has a very low viscosity under the condition of zero magnetic field, which is beneficial for the actuator to obtain the lower limit of the regulating force value as low as possible.

High yield strength:

Under the action of an external magnetic field, it has a high yield strength, which is beneficial to the actuator to obtain the upper limit of the adjustment force value as high as possible.

Good wide temperature:It can be used normally for a long time in the range of -45℃-130℃.

Good settlement resistance:The settling rate is low after standing for a long time, and no hard settling occurs.

Good redispersibility:It is very easy to redisperse uniformly after prolonged standing and settling.

Good thickening resistance:No IUT (use thickening) phenomenon occurs after long-term use.

Good anti-aging properties:Long-term use is not easy to cause aging due to factors such as oxidation, temperature, light, and mechanical force.

Good liquidity:It has excellent fluidity after the external magnetic field is removed.

Good sealing compatibility:

Using special materials and formulas, it has good compatibility with sealing materials, which is beneficial to ensure the reliability of sealing.

Good friction reduction:The friction coefficient with the contact surface is low, which is beneficial to improve the mechanical performance of the actuator.

Good abrasion resistance:Long-term use has little effect on contact surface wear, which is beneficial to improve the durability of the actuator.

Green:It is prepared with environmentally friendly materials and environmentally friendly processes, and is environmentally friendly.

Some project test examples

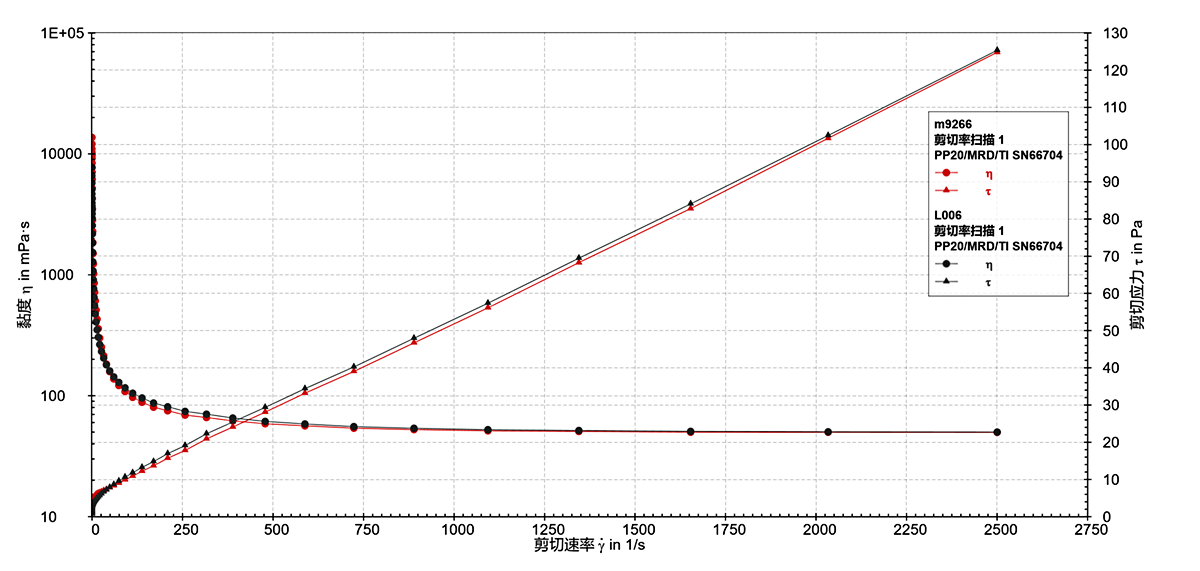

1、Zero field viscosity test

The industry generally defines the slope of the "shear stress-shear rate curve" between 800 1/s - 1200 1/s as zero field viscosity. The picture below shows the comparative test of Keyi International's products and a foreign brand.

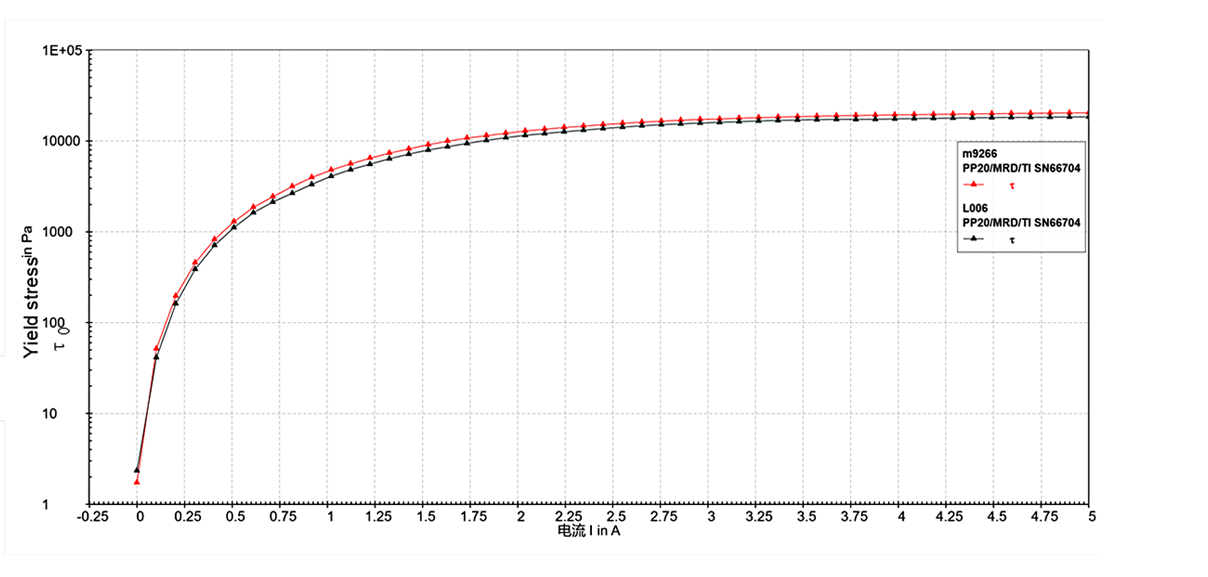

2、Yield strength test

The picture below shows the yield strength comparison test of Keyi International products and a foreign brand. Under the same conditions, the higher the yield strength, the greater the control force the actuator can provide.

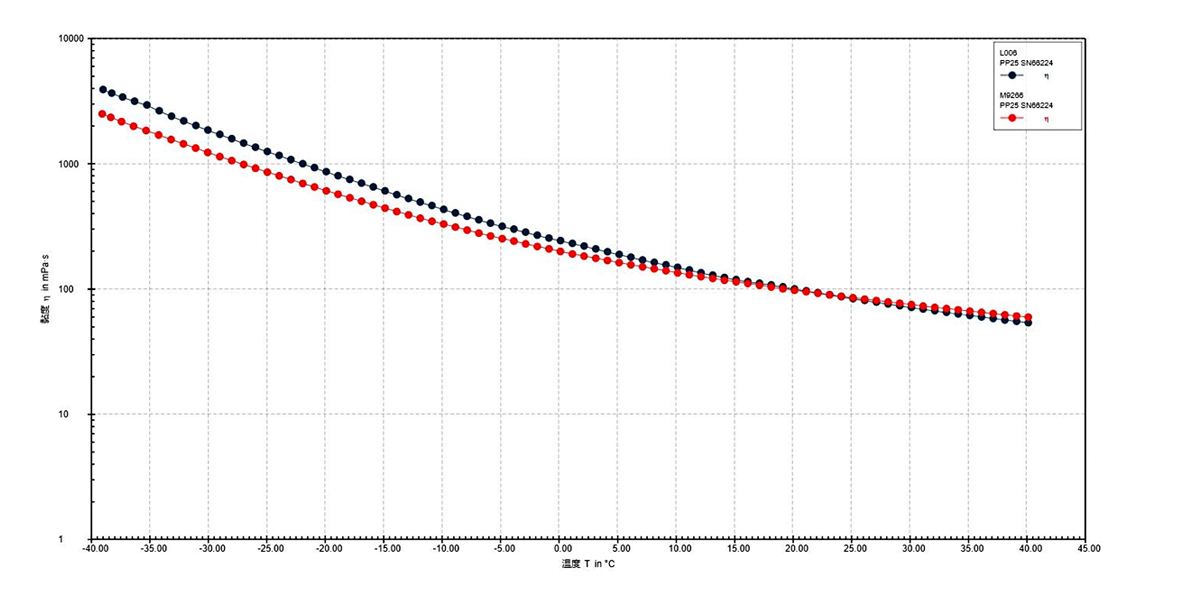

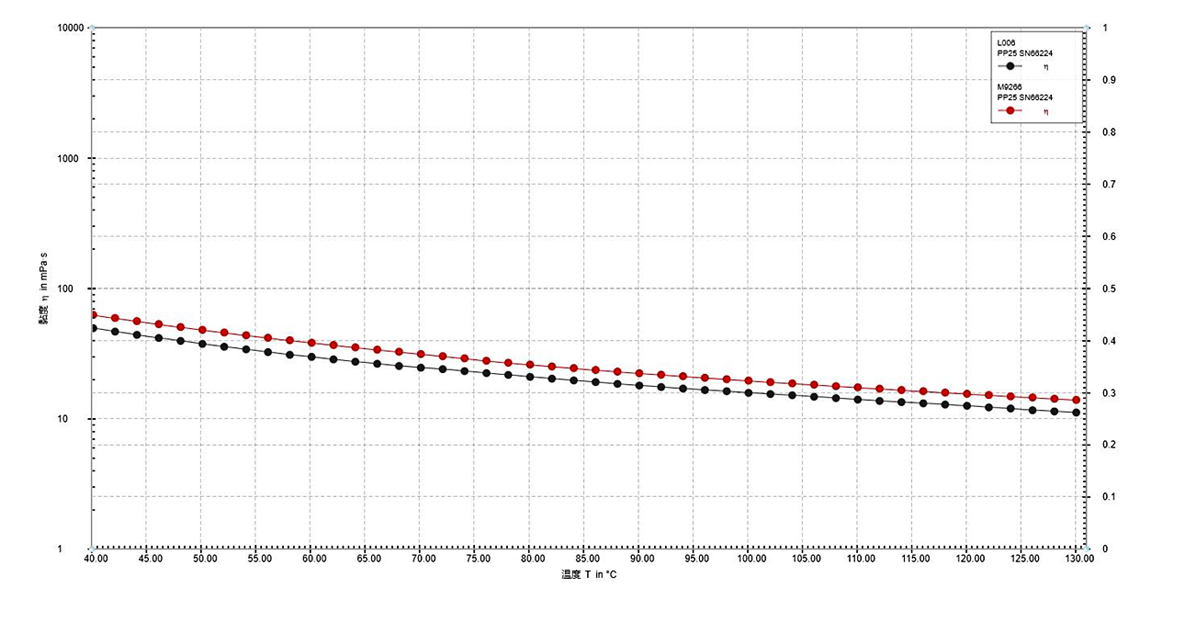

3、Visco-temperature characteristic test

The following picture shows the comparison test of the viscosity-temperature characteristics of Keyi International products and a foreign brand product. Under the same conditions, the flatter the viscosity-temperature curve, the better the product performance.

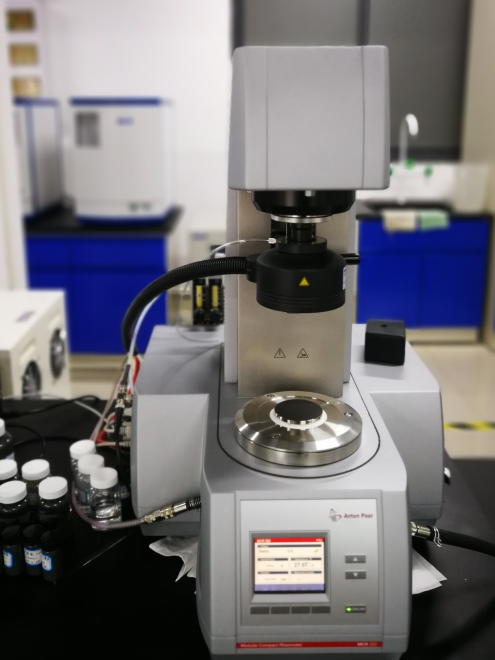

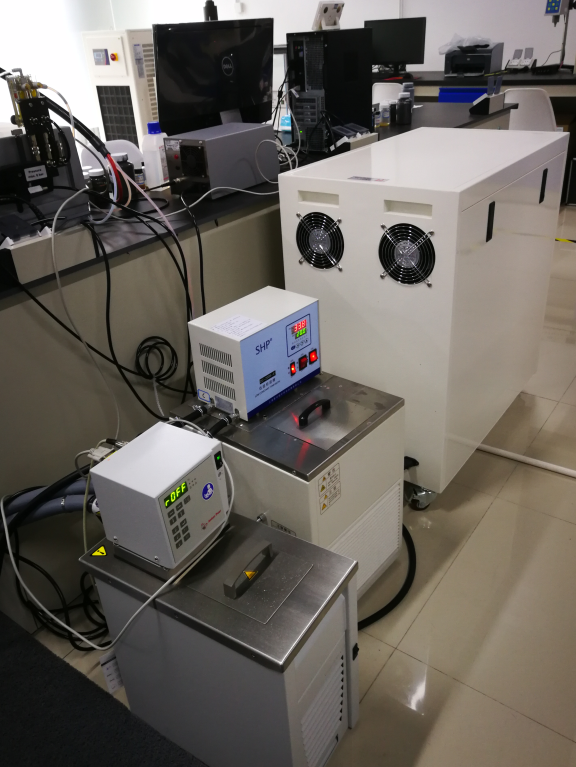

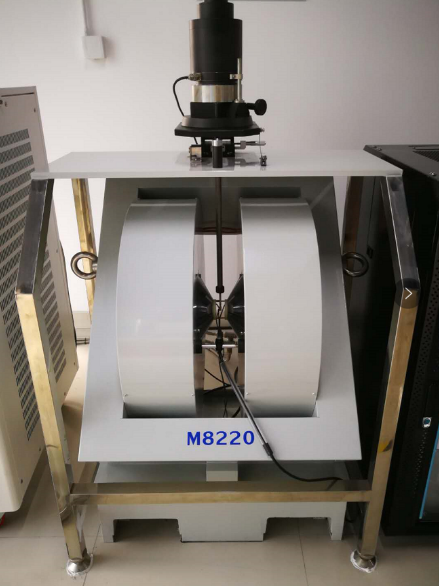

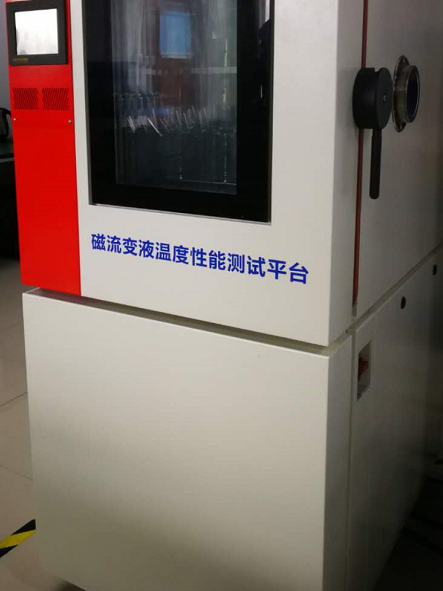

Part of the test and test equipment display

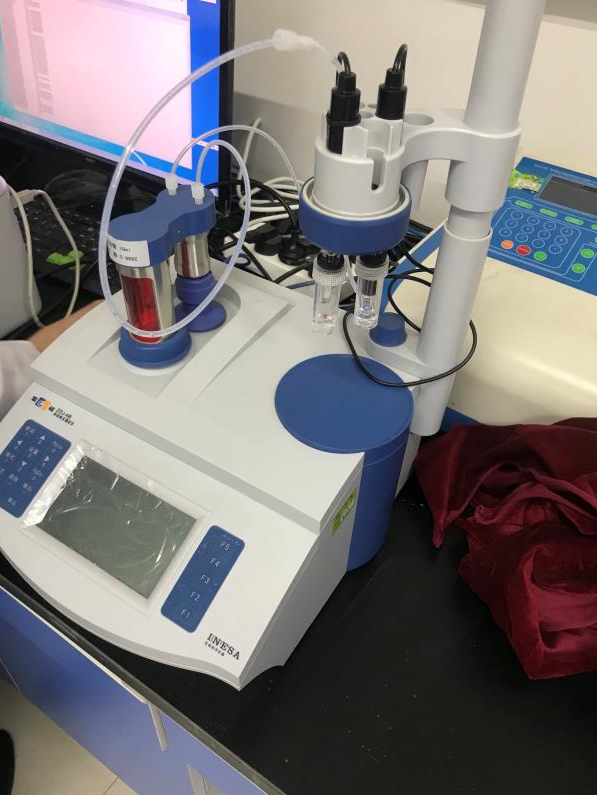

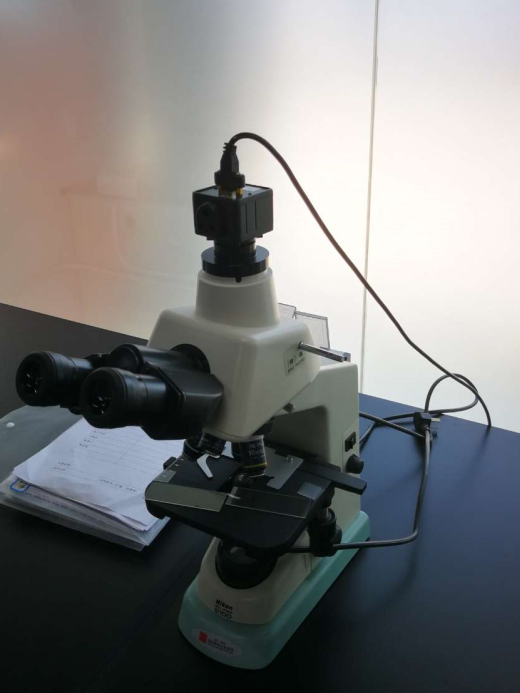

Magnetic characteristic analyzer and its auxiliary equipment

Magnetorheological Fluid Durability Test Platform Test formula sample storage cabinet |